Description

CellarPro Ducted Split Air Handler 1/4 Ton AH3500Sx-ECX #36245

CellarPro AH3500Sx-ECX Cooling Unit (P/N 36245). CellarPro engineered the AH3500Sx-ECX ducted cooling system to provide maximum cooling power and adjustable humidity control for cellars up to 900 cubic feet. The evaporator and the condensing unit each can be ducted up to 100 equivalent feet (50 equivalent feet per duct.) As a split system, the evaporator can be separated from the condensing unit up to 100 feet, allowing the noise and heat from the condensing unit to be located away from interior living areas. Designed for internal installations, the AH3500Si-ECX includes energy-efficient independent variable-speed EC fans with a low setting for quieter operation and a high setting for maximum power.

All air-cooled refrigeration equipment requires fresh air intake to dissipate the heat generated by the cooling unit. The fresh air intake CANNOT come from the wine cellar space – it must come from space outside the cellar.

3354 SENSIBLE BTUH @ 55F.

CellarPro’s AH3500Sx-ECX ducted cooling units (1/4 Ton Nominal) are engineered for wine cellars up to 900* cubic feet in both commercial and residential wine cellars. This ducted unit uses 8-inch ducting and requires insulated ducting on the cold side.

This unit maintains optimal cellar temperature and humidity conditions in extreme conditions up to 110F. AH3500Si units use energy-efficient EC fans and are significantly quieter than comparable units from other brands. Visit our Learning Center for data tables, performance charts and product comparisons among different brands.

When the condensing unit will be exposed to or pulling air that is below 40F, our Compressor Heater (P/N 1727) is a required addition to protect the compressor. For installation of the condensing unit in environments below 20F down to -20F, our Fan Cycling Switch (P/N 6972) is required in addition to the Compressor Heater, and Electronic Configuration is required.

*Assuming R19 insulation throughout the cellar, 55F inside the cellar and 85F outside the cellar. Cold-side ducting, glass and/or uninsulated walls, extreme humidity, altitude and other factors may affect the sizing calculation.

Our cooling units are designed to be used in properly-constructed wine cellars that are adequately insulated, airtight and sealed with a vapor barrier. In improperly-constructed cellars, the cooling unit will create excess condensation, leading to damage and premature failure of your cooling unit (not covered by warranty).

- Now with energy-efficient EC Fans on both the cold and hot sides, save $300.77 in annual energy costs vs AC fans (assumes 75% runtime and $0.15/kWh)

- CellarPro Air Handlers are engineered to be ducted with 8-inch insulated ducting on the cold side (evaporator) and/or 8-inch ducting on the hot side (condensing unit), allowing the equipment can be located out-of-sight where it won’t be heard.

- High-output EC fans provide more airflow and variable speed settings for your choice of cooling power.

- Optional integrated humidifier provides the ultimate control of moisture levels inside your cellar.

- Optional integrated heater provides heat for wine cellars that are exposed to temperatures below 55F.

- Extra-large coils generate maximum cooling power inside the cellar.

- Excess condensate is managed through an extra-large 1/2″ drain line, amply sized to reduce blockages.

- Commercial-grade Electrofin coating protects the evaporator coils from leaks and corrosion.

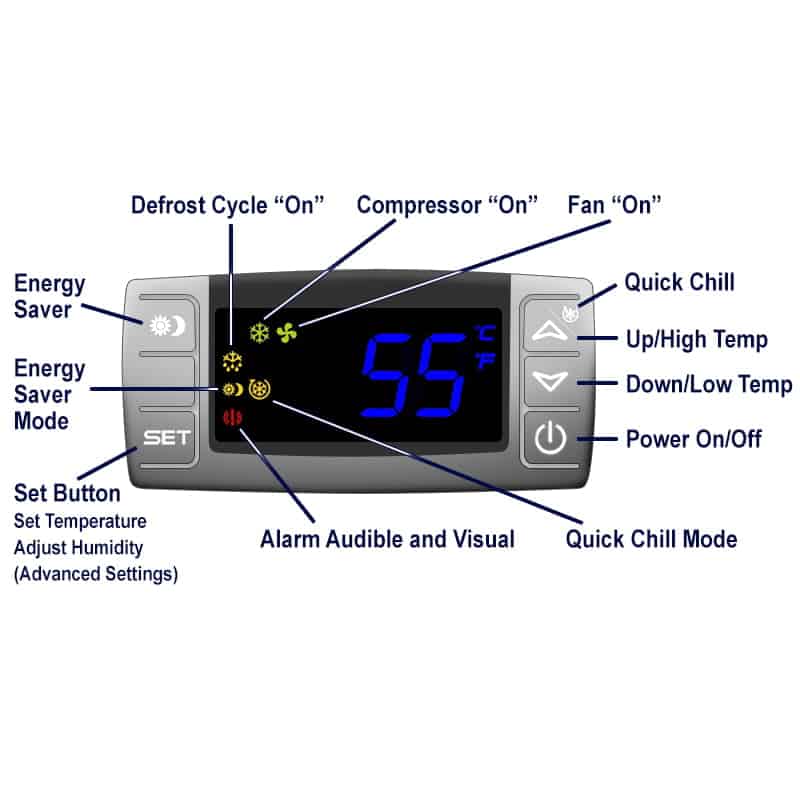

- Intuitive LED display panel mounted on the evaporator with digital programmable thermostat is simple and easy to use. Remote thermostat is available as an upgrade.

- Energy-saver mode, quick-chill mode, and auto-defrost cycle provide convenient solutions to common cellar needs.

- Temperature set point range is 47F to 62F when the cooling unit is properly sized.

- Unit operates with minimal vibrations and less noise than comparable units from competitors.

- Audible and visual alarms and maintenance-needed indicator protect the cooling unit and the wine cellar.

- Remote probe for the cellar (bottle probe) and duct adapters are included as standard equipment

- Factory-installed Expansion Valve ensures maximum operating precision and range.

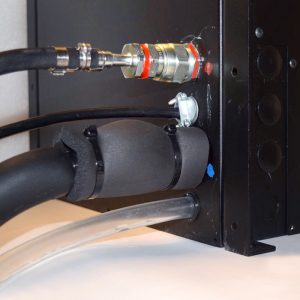

- Removable steel case and refrigerant access valve provides access to the internal components for servicing and repair.

- Cooling system is fully-charged with refrigerant and ready-to-use out of the box.

- CellarPro’s 2-Year/5-Year Warranty, the most thorough in the industry, protects the unit against manufacturing defects.

- An optional Extended Warranty (P/N 7528) is available for additional protection.

- ETL Tested and Certified to rigorous UL Standards for safety.

CONFIGURATIONS:

- CellarPro AH3500Sx-ECX units are designed to be ducted, with the evaporator near (or inside) the cellar, and the condensing unit in a remote interior location up to 100 feet away.

- The evaporator and the condensing unit each can be ducted up to 100 Equivalent Feet (50 Feet per Duct) with 8-inch ducting .

- CellarPro’s split configuration allows multiple ducting alternatives, as follows.

- Collars or grills for EXHAUST (ie Supply) are located at the front (shown at left), top or rear of the cooling system, and are interchangeable to meet your specific requirement.

- Collars or grills for INTAKE (ie Return) are located at each end (left: evaporator, and right: condenser), and include professional-grade air filters to protect the unit.

- We recommend pulling the fresh air intake (hot-side) from a temperature-controlled environment (must be outside the cellar). If the hot-side exhaust will be directed to a different space than the intake, always make sure that both spaces are sufficiently voluminous so that you don’t run into issues with negative pressure.

- A bottle probe temperature sensor (10′ cord) plus your choice of duct collars, indoor grills and blank plates are included in the price of the cooling system.

- CellarPro Air Handler Split systems offer a choice of 110V / 60Hz wiring and power configurations:

- Two permanent power connections for the evaporator (2.0 amps / 15 amp circuit breaker) and the condensing unit (8.7 amps / 15 amp circuit breaker). This wiring configuration is recommended for Valve Control.

- One permanent power connection for the entire system (15 amp circuit breaker). In this configuration, the condensing unit must be wired to the evaporator, and must be used with Electronic Control.

- The amp data above is not valid when the integrated heater and/or humidifier are configured with the cooling unit – please consult those Owner’s Manuals for the additional amps required when using those upgrades.

- When the control panel is difficult to access, we offer a remote control display kit which is wired to the cooling unit and allows the digital display to be mounted inside or outside the cellar.

- The condensing unit requires 12 inches of unobstructed space in front of the coils, and requires approx. 600-700 CFM of ventilation when installed in a confined space.

- For installations in environments below 40F, AH3500Sx-ECX units require our Compressor Heater (P/N 1727) (included).

- For installation in environments below 20F down to -20F , Electronic Control is the required configuration, and our Fan-Cycling Switch (P/N 6972) is required in addition to the compressor heater (both sold separately).

- The evaporator should never be exposed to temperatures below 32F.

- Access to the left and right side of the evaporator unit is required for installation.

- All split systems must be installed and charged on site by a qualified HVAC professional. Line-set equivalent feet must be calculated in accordance with ASHRAE guidelines; refer to our Line Sizing Chart for more information.

- A CellarPro cooling unit must always be used in the upright position, and should never be operated on its side or upside down.

- We ship these units strapped to a pallet via common carrier with curbside delivery. Inside delivery is available for an additional charge.

- To activate your warranty, you must complete and return our Installation Checklist.

OPTIONS:

- Cold Temperature

- Compressor Heater #1727: protects the unit when installed in environments that drop below 40F down to 20F (Included)

- Fan Cycling Switch #6972: supports the unit in temperatures below 20F and as low as -20F when configured with Electronic Control and combined with our compressor heater.

Filters & Grills- Use our filter & grill guide to find the cooling unit filter or duct filter and/or duct grill that is appropriate for your cooling unit.

Remote Thermostats, Displays & Probes

- Networkable Thermostats #27346 and #27310: connect your cooling unit to a networkable, wi-fi enabled thermostat (sold separately). Must be ordered at the same time that the equipment is ordered. Other limitations apply – read the networkable thermostat description for more information. Includes 10 feet of wiring.

- Remote Display #1603: lets you place the digital panel wherever you want, whether inside or outside the cellar. Includes 10 feet of wiring. Additional wiring is available at a cost of $0.50 per additional foot.

- Bottle Probe #1434: this remote thermostat with a 10-foot cord overrides the thermostat on the face of the cooling unit, and allows it to monitor air or liquid temperatures at various locations inside the cellar – included.

- Bottle probe extension cords are available in 25-foot (#1780) and 50-foot (#1781) lengths.

Heating & Humidification- Integrated Heater 900W #7237: adds 900 watts of heat through the cooling system when the cellar is in an unheated environment and will be exposed to temperatures below desired wine storage temperatures.

- Integrated Humidifier #7236: provides humidification with digital control inside the cellar when attached to an external water line.

Specs:

- Size: 18 3/5w x 18 3/5d x 19 3/10h (in) (Evap)Weight: 225 lbsEvaporator Dimensions:

– 60 lbs (no humidifier)

– 18.6w x 18.6d x 19.3hCondensing Unit Dimensions:

– 111 lbs

– 18.6w x 18.6d x 19.3hPower:

– CellarPro Air Handler Split systems offer a choice of 110V / 60Hz wiring and power configurations:- Two permanent power connections for the evaporator (2.0 amps / 15 amp circuit breaker) and the condensing unit (8.7 amps / 15 amp circuit breaker). This wiring is recommended for Valve Control configurations.

- One permanent power connection for the entire system (15 amp circuit breaker). In this configuration, the condensing unit must be wired to the evaporator, and must be used with Electronic Control.

– Startup Amps: 30.0 Amps

– Running Amps Cord-Connected: 9.0 Amps

– Total Watts: 558 (medium fan speed)

– 1/4 Ton NominalBTUH @ 55F

– Low Fan Speed: 2778

– Med Fan Speed: 3212

– High Fan Speed: 3354Decibels

Evaporator Decibels

– Low Fan Speed, Ducted: 38 dbA

– Med Fan Speed, Ducted: 44 dbA

– High Fan Speed, Ducted: 52 dbACondensing Unit Decibels

– Low Fan Speed, Ducted / Non-Ducted: 43 dbA / 56 dbA

– Med Fan Speed, Ducted / Non-Ducted: 50 dbA / 63 dbA

– High Fan Speed, Ducted / Non-Ducted: 55 dbA / 68 dbA