Description

CellarPro Recessed Ceiling Mount 8000Scmr #34219

6088 BTUH @ 55F.

CellarPro’s 8000Scmr Recessed Ceiling Mount split cooling system features a pair of evaporators (3/4 Ton Nominal) that are designed to be recessed in the ceiling. This system is suitable for wine cellars up to 2000* cubic feet in both commercial and residential wine cellars.

Performance testing shows that this system maintains optimal cellar temperature and humidity conditions in extreme conditions up to 110F more effectively than similar units from competing brands. 8000Scmr units also are significantly quieter than comparable units from other manufacturers.

All ceiling-mount systems include our remote display with 20-feet of low-voltage wiring (additional wiring available upon request) and an integrated condensate pump as standard equipment. Visit our Learning Center for data tables, performance charts and product comparisons among different brands.

*The cellar size assumes that the cellar is constructed with a proper vapor barrier, insulation of R19 or better in all walls and ceiling (ie no glass or uninsulated concrete), a setpoint of 55F inside the cellar and ambient temperatures up to 85F outside the cellar.

DESCRIPTION:

CellarPro Ceiling Mount Recessed 8000Scmr (P/N 34219). CellarPro engineered the Ceiling Mount Mini-Split 8000Scmr cooling system to provide maximum cooling power and adjustable humidity control with a pair of ceiling-mounted evaporators that can be recessed in the ceiling and therefore hidden from view. The condensing unit can be configured for indoor or exterior installations, and the evaporator includes a variable-speed fan with a low setting for quieter operation and a high setting for maximum power.

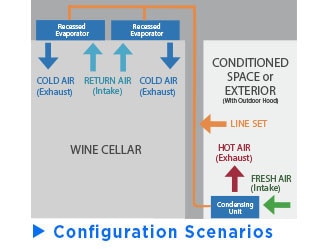

All air-cooled refrigeration equipment requires fresh air intake to dissipate the heat generated by the cooling unit. The condensing unit must be installed outside the cellar in a location that provides ample space and access to fresh air.

- This unit is designed to separate the heat and noise from the condensing unit from interior living spaces, and can be configured to operate indoors or outdoors in extreme temperature conditions ranging from -20 to 110F.

- Our Evaporators are built with high-output centrifugal fans which include variable speed settings for your choice of maximum cooling power at the high fan speed, or quieter operation (57 decibels) at the low fan speed.

- Adjustable humidity control combines a high-output compressor with flexible fan cycles to maintain a recommended level of moisture inside your cellar.

- Extra-large coils generate maximum cooling power inside the cellar.

- Excess condensate is managed through an internal integrated condensate pump and a 1/4″ drain line that exits from a choice of knockouts in the evaporator. The pump has automatic overflow protection.

- Commercial-grade Electrofin coating protects the evaporator coils from leaks and corrosion.

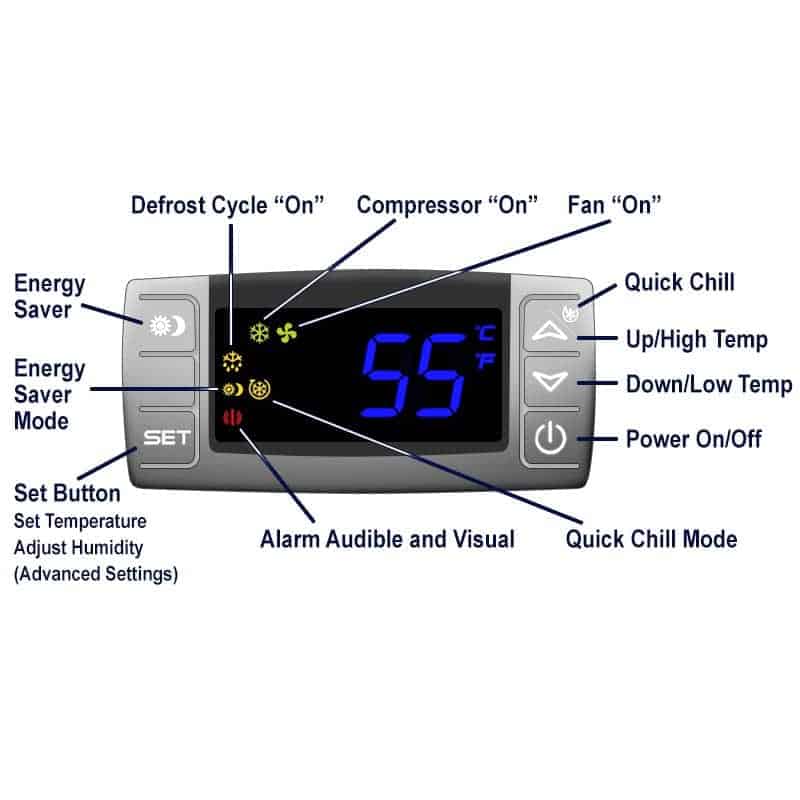

- Remote LED display panel and digital programmable controls includes 20-feet of wiring and can be mounted inside or outside the cellar.

- Quick-chill mode, and auto-defrost cycle provide convenient solutions to common cellar needs.

- Temperature set point range is 47F to 62F when the cooling unit is properly sized.

- Unit operates with minimal vibrations and less noise than comparable units from competitors.

- Audible and visual alarms and maintenance-needed indicator protect the cooling unit and the wine cellar.

- Common dedicated 25-amp circuit is required to power the unit.

- Factory-installed Expansion Valve and Liquid Line Solenoid Valve (optional) ensure maximum operating precision and range.

- Refrigerant access valve provides access to the internal components for servicing and repair.

- Sight Glass and Liquid Line Filter/Drier are included for easy installation and maintenance.

- Oversized Receiver allows for long line sets up to 100 equivalent feet and up to 30 vertical feet.

- Auto-reset high-pressure switch protects the system by interrupting power to the compressor when system pressure is too high.

- Evaporator and Condensing Unit are factory-pressurized and shipped with dry nitrogen to ensure leak-free installation.

- CellarPro’s 2-Year/5-Year Warranty, the most thorough in the industry, protects the unit against manufacturing defects.

- An optional Extended Warranty (P/N 31489) is available for additional protection.

- ETL Tested and Certified to rigorous UL Standards for safety.

CONFIGURATIONS:

-

- CellarPro Mini-Split 8000Scmr units are designed to be installed with the pair of evaporators recessed in the ceiling above the cellar, and the condensing unit in a remote location.

- Our Split refrigeration systems offer a choice of wiring:

- The Condensing unit can be electronically controlled by and wired to the Evaporator (single power source on the Evaporator side). This configuration allows the Condensing unit to be used in temperatures down to 20F with the addition of our compressor heater, or down to -20F with the addition of our fan cycling switch AND compressor heater. This configuration requires a 15-amp dedicated circuit breaker for 3000Scmr and 4000Scmr systems, and a 25-amp dedicated circuit breaker for 6000Scmr and 8000Scmr systems.

- The Condensing unit can be controlled by a Solenoid valve (dual power source, one each to the primary Evaporator and Condensing units.) This configuration allows the Condensing unit to be used in temperatures down to 20F with the addition of our compressor heater. This configuration requires the primary evaporator to be wired to a 15-amp circuit breaker, and the condensing unit to be wired to a dedicated 15-amp circuit breaker for 3000Scmr and 4000Scmr systems, a dedicated 20-amp circuit breaker for 6000Scmr systems, and a dedicated 25-amp circuit breaker for 8000Scmr systems

- The condensing unit requires 12 inches of unobstructed space in front of the coils, and requires approx. 600-700 CFM of ventilation when installed in a confined space.

- For outdoor installations, we offer an outdoor hood to protect the condensing unit from weather. All outdoor hoods include a compressor heater.

- The evaporators should never be exposed to temperatures below 32F.

- Access to the bottom of each evaporator is required for installation.

- All split systems must be installed and charged on site by a qualified HVAC professional. Line-set equivalent feet must be calculated in accordance with ASHRAE guidelines; refer to our Line Sizing Chart for more information.

- A CellarPro cooling unit must always be used in the upright position, and should never be operated on its side or upside down.

- We ship these units strapped to a pallet via common carrier with curbside delivery. Inside delivery is available for an additional charge.

- To activate your warranty, you must complete and return our Installation Checklist.

OPTIONS:

Cold Temperature

- Compressor Crankcase Heater #1727:protects the unit when installed in environments that drop down to 20F.

- Fan Cycling Switch #6972: supports the unit in temperatures below 20F and as low as -20F when combined with our compressor heater.

Hoods

Outdoor Hood #2011: allows you to install the condensing unit outdoors; all outdoor hoods include a Compressor Heater #1727.

Bottle Probe

- Bottle Probe #1434: this remote thermostat with a 10-foot cord overrides the thermostat on the face of the evaporator, and allows it to monitor air or liquid temperatures at various locations inside the cellar.

- Extension cords available in 25-foot (#1780)and 50-foot (#1781)

CellarPro VS Series Enhanced Warranty #1836

Compressor Crankcase Heater #1727

Remote Control and Display #1603:

Duct Intake Hood (Cold Side) Low RH #7408

Duct Intake Hood (Cold Side) High RH #7427

Duct Intake Kit (Cold Side) Low RH#1476

Duct Intake Kit (Cold Side) High RH#7426

Specs:

- Capacity:6,088 BTUH @ 55F

- Size:71 3/4 x 14 1/4 x 12 7/8 (in)

- Weight:196 lb

- Power/Rating:115V AC / 60 Hz

System Amps:

– Common dedicated 15-amp Evaporator and 25-amp Condenser circuit (valve control) or 25-amp circuit (electronic control) is required to power the unit.

– Startup: 51.0 Amps

– Unit Amp Rating: 14.7 Amps (high fan speed)

– Total Watts: 1242 (high fan speed)BTUH @ 55F:

– Low Fan Speed: 5042

– Medium Fan Speed: 5831

– High Fan Speed: 60883/4 Ton NominalEvaporator Decibels

– Low Fan Speed: 57 dbA

– Medium Fan Speed: 61 dbA

– High Fan Speed: 69 dbA

Condensing Unit Decibels

– Indoor: 67

– Outdoor: 65Capacity: 6088 BTUH @ 55FSizing Table: Click here to view sizing table - Warranty:2 Years (Entire System) To activate your warranty, you must complete and return our Split Installation Checklist.

Optional Extended Warranty sold separately. - SKU:8000Scmr

- UPC:077757011283

Evaporator Cut Sheet, Mounting Instructions, Split Systems Refrigerant Piping Handbook, 3000-8000Scmr-Owners-Manual Refrigerant Piping Diagram, Front Ducted Evaporator Cut Sheet, Wiring Diagram – Dual Power Valve Control, Condensing Unit _ Hood